3 Easy Facts About Premier Aluminum Llc Shown

8 Simple Techniques For Premier Aluminum Llc

Table of ContentsThe Best Guide To Premier Aluminum LlcGetting My Premier Aluminum Llc To WorkRumored Buzz on Premier Aluminum LlcPremier Aluminum Llc Can Be Fun For Everyone

(https://premieraluminum.edublogs.org/2024/12/12/top-rated-aluminum-casting-company-why-premier-aluminum-llc-stands-out/)Generally, a purchaser's key obligation was to locate competent and receptive distributors. Sometimes, buyers assumed that any type of provider ready to contractually satisfy the acquisition requirement was certified. However, utilizing reduced expense and unqualified distributors can cause top quality problems, and lost time and cash in the long run. To aid you through the procedure, below are some things to think about when picking the best steel spreading provider.

A company that only uses the investment casting process will try to market you on why that procedure is best for your application (Aluminum Castings). Yet what happens if making use of the sand spreading procedure is best for you and your demands? Instead, try to find a distributor that supplies an array of casting procedures so the most effective choice for YOU is chosen

If collaborating with a solitary resource for all of your casting needs is very important to you, the distributor requires to be diverse in its capabilities. When incorporated with other integrated capacities, this can help streamline and press the supply base. When selecting the right spreading distributor, cautious consideration needs to be offered to high quality, service, and rate.

The Best Strategy To Use For Premier Aluminum Llc

Customers progressively select spreading providers that have machining capabilities. This can prevent conflict if problems are discovered during machining. If a 3rd party is machining, it might cause "finger-pointing" about who is at mistake. Is it a casting issue or a machining concern? If the casting vendor uncovers a concern during machining, the issue is settled quicker without any conflict over whose mistake it is.

What do you need from your casting distributor? Are you looking for a person to just provide a steel element to your doorstep or do you need more?

Some foundries are limited or specialized. Make sure the distributor can fulfill all your product or alloy needs to get rid of the demand for numerous vendors.

The Ultimate Guide To Premier Aluminum Llc

Research the provider's web site. Talk with a sales associate or company affiliate. Ask a great deal of questions. Visit their center. Get an understanding of what they can do for you and if you can see on your own developing a solid, shared relationship with them.

Aluminum is likewise light-weight and has good rust resistance, making it perfect for applications where weight and durability are essential elements. Furthermore, light weight aluminum casting is a cost-effective technique of production, as it requires less energy and sources than various other techniques. Iron spreading, on the various other hand, involves putting liquified iron right into a mold to produce a wanted form.

The Best Guide To Premier Aluminum Llc

Iron casting is additionally able to endure heats, making it appropriate for usage in applications such as engine components and industrial machinery. Nevertheless, iron spreading can be much more costly than aluminum spreading as a result of the higher cost of resources and the power required to thaw the iron. When choosing between aluminum casting and iron casting, it is necessary to consider the details requirements of the application.

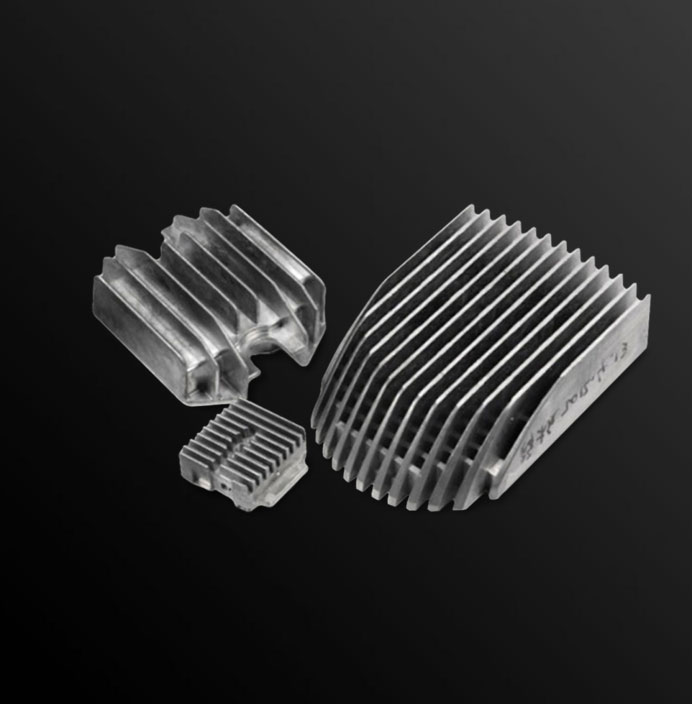

In final thought, both light weight aluminum spreading and iron casting have their own distinct advantages and drawbacks. There are three sub-processes that drop under the category of die spreading: gravity pass away spreading (or long-term mold and mildew casting), low-pressure die spreading and high-pressure die spreading. To obtain to the finished product, there are three key alloys utilized as die spreading material to pick from: zinc, light weight aluminum and magnesium.